| When RVS-master will not help ! |

| 1.If compression rings or scraper seal rings are heavily worn. |

|

| 2.If scraper seal rings lie inside the piston. |

|

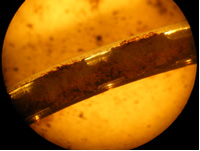

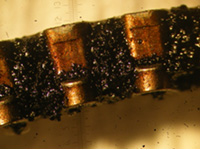

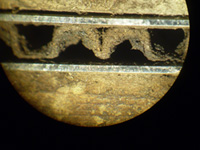

| 3.If scraper seal rings and expander are clogged with oil or carbon disintegration products. |

|

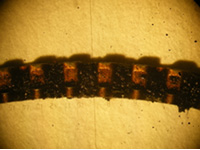

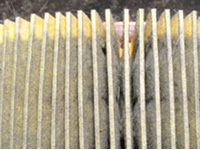

| 4. If compression rings or scraper seal rings are clogged with sand or dust due to tardy changed air filter. |

|

| 5. If there are clogging, corrosion and heavy wear of details and when due to the change of configuration there is no contact between details. |

|

| 6. If oil filter is clogged with wear products, carbon and oil destruction and is not able to let through fine-dispersed parts (up to 10 micron). |

|

| 7. If overheating of engine occurred before the treatment. |

|

| 8. If, as a result of wear or overheating, spacing and details size were changed and changes occurred in symmetry units. |

|

| 9. If there are details breaks and large splits. |

| 10. If oil pump and oil channels are clogged and impede normal oil passing. |

|

| 11. If incorrect product category is used. |

| 12. If right after RVS treatment mechanism is not operating for a long time. |

|

| 13. If low-grade fuel that contains excess impurities is used. |

|

| 14. If application instruction is not observed and manufacturer’s recommendations are not taken into account. |